The Main Principles Of Motorcycle Parts New Zealand Specialists

Unknown Facts About Motorcycle Parts New Zealand Specialists

Table of ContentsRumored Buzz on Motorcycle Parts New Zealand Specialists8 Easy Facts About Motorcycle Parts New Zealand Specialists ShownThe Best Strategy To Use For Motorcycle Parts New Zealand SpecialistsThe Motorcycle Parts New Zealand Specialists PDFsMotorcycle Parts New Zealand Specialists Can Be Fun For AnyoneMotorcycle Parts New Zealand Specialists Fundamentals ExplainedSome Known Details About Motorcycle Parts New Zealand Specialists The Main Principles Of Motorcycle Parts New Zealand Specialists

So, get to out to among our experts today.CNC machining modern technology is rapidly becoming the centerpiece of various production processes around the globe as a straight result of its lots of advantages over various other methods. Additionally, the sectors that make bikes have actually jumped on board with this trend. One of the most cutting-edge companies are currently developing their engine elements and wheels using machining techniques initially developed for motorcycle parts.

On the other hand, the impacts of industry are the key focus of this short article. Allow's get directly into it. You may be asking yourself why we utilize. It is not tough to fathom the elements that caused this outcome. Since we have your interest allow us describe the reasoning behind this contemporary development in the motorbike production industry.

The Greatest Guide To Motorcycle Parts New Zealand Specialists

In addition, you have total control over the appearance of the components, even to the minute details. Sometimes, motorcyclists might determine to improve their adventure by installing aftermarket elements or modifying the bike's remodeling. Once more, computer mathematical control (CNC) machining is one of the most functional method. Upgrades may be of any kind and style you want.

Some Known Facts About Motorcycle Parts New Zealand Specialists.

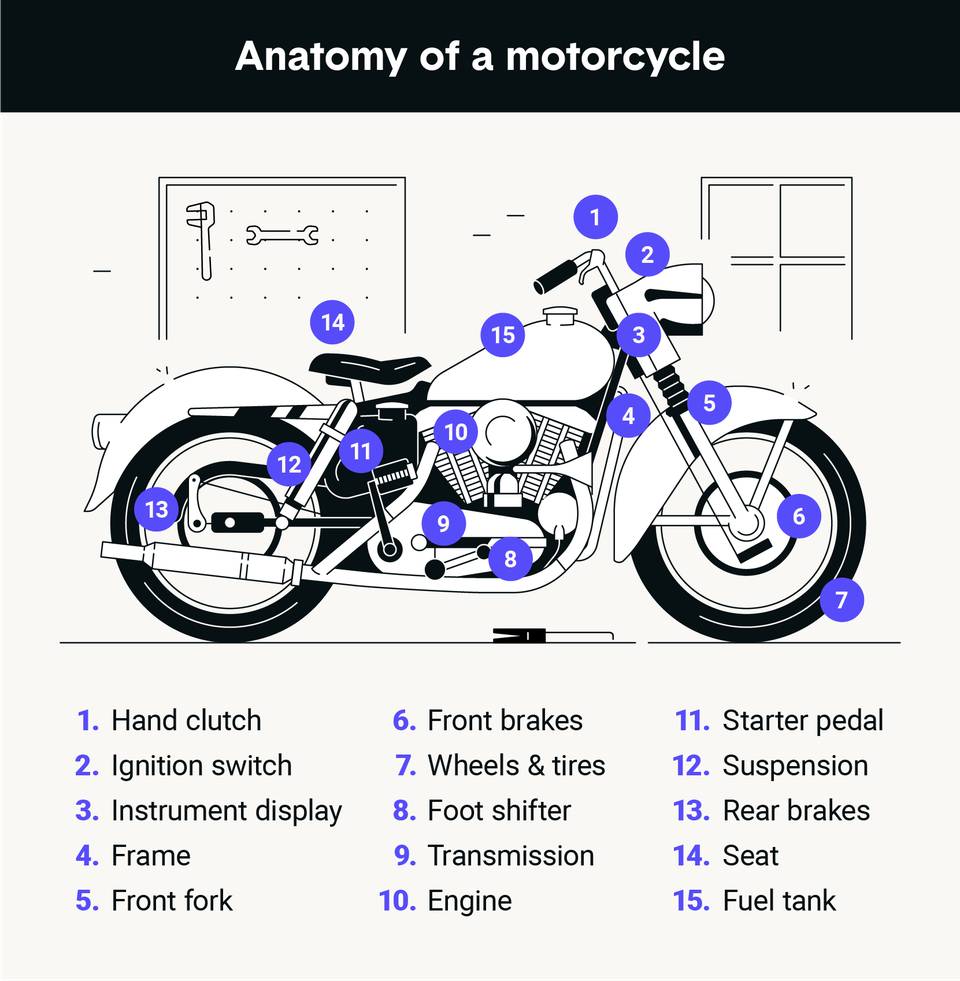

CNC machining might be utilized to make virtually all of a motorcycle's metal and plastic components. To proceed, we'll review numerous machined components for bikes.

When personalizing the wheels, the disks are where the focus ought to be. The bulk of them are constructed of light weight aluminum. Light weight aluminum alloys are widely known for the outstanding machining abilities that they have. Milling procedures are made use of to acquire the wanted degree of wheel personalization. Another aspect of the bike that might be personalized is the tires.

How Motorcycle Parts New Zealand Specialists can Save You Time, Stress, and Money.

When it comes to a car (or a motorcycle), the most essential element is the engine. Several individuals mention it as the "heart" of the auto. On the other hand, the camshaft, the cylinder head, and the pistons have a tendency to be detailed and call for styles with a high level of precision.

Use only high-quality products, nonetheless, considering that these lights are critical for the security of motorcyclists and other motorists or people on the roadway, especially at night. Motorbike fronts lights have three main components: the bulb, or light source, the lens, and the housing.

Milling procedures with a remarkable coating would result in the lenses having a reflective quality that resembles that of a mirror. The cover, on the other hand, is not composed of vulnerable products; instead, it is built out of hard polymers that can be machined right into even more detailed patterns.

The Facts About Motorcycle Parts New Zealand Specialists Revealed

They commonly have sophisticated geometries with a riches of min information. Motorbike makers typically cast these elements, however only for the manufacturing of bespoke components. Nevertheless, CNC machining is the approach of option when creating distinct pieces. Machining on five axes in today's globe is the means whereby any kind of style form may be realized.

Pick Runsom for your personalized bike parts! We have the ability to make complex and stylish parts making your motorbike matchless.

Right here are a few instances of metals often utilized in motorbike part machining. Light weight aluminum is the key product made use of by business specializing in generating personalized motorbike parts to produce many of these parts - Motorcycle Parts New Zealand Specialists.

Zinc refers to one more steel that is very light in weight and has fantastic machining top qualities due to its high mechanical toughness. This material might be developed into practically any form and keeps its dimensions well. Even mission-critical elements that need a original site high level of accuracy may take advantage of their usage.

Motorcycle Parts New Zealand Specialists for Dummies

An additional metal that go to this site sees hefty use in the manufacturing of CNC-customized parts is magnesium. It is amongst the lightest steels that are currently obtainable and has exceptional machinability features and toughness compatible with its low weight. One of the drawbacks of magnesium is that its dirt might conveniently ignite.

As a result of its exceptional machinability and weldability, stainless-steel is an alloy that is especially appropriate for CNC processes. Along with this, they have terrific corrosion resistance and a high visual allure. Their most common usage in producing different bike elements is fasteners, such as screws and screws. Their low susceptibility to oxidation and rust makes them suitable for this use.

4 Easy Facts About Motorcycle Parts New Zealand Specialists Shown

It appears that CNC transforming and milling are the foundational processes. In addition, it requires keeping bars of product, most typically plastic or steel, in placement and after that turning a cutting tool to remove sections of the product as the product is turned.

These techniques are equally essential and generate components with high accuracy and consistent high quality. The processes help boost the general high quality of the machined motorbike parts.

Little Known Questions About Motorcycle Parts New Zealand Specialists.